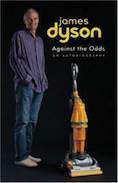

RATING: 8/10

The crazy story of James Dyson and his super-human persistence getting his revolutionary Vacuum to market. A super inspiring story for instilling the want to make things and fight industry giants like great inventors from the past.

Notes:

To use a Hollywood cliché, it is said to be an overnight success takes years of effort. So it has proved with me. There were twenty years of debt, personal overdraft liabilities, at times, of millions of pounds.

There have been no massive advertising campaigns (not from me at any rate, though there have been campaigns from the big boys designed to damage me, or at least to limit the damage I have done to them) and I have not taken over the market with a barrage of free offers, bombastic rhetoric, and gilded promotions. There have been no free air tickets with the Dual Cyclone. It has all happened, I really believe, because of the intrinsic excellence of the machine; because it is a better vacuum cleaner than anything that has gone before; and because it looks better than anything like it has every looked.

The first thing to forget is any notion that you have to be a qualified engineer to make an impact on engineering. I studied only art subjects at school and slipped into the Royal College of Art through the back door. I fiddled with wood for a while and then – when it was still looked upon as barbarian at the gate – got into plastic, and drifted into product design. Convinced engineering was no more than a state of mind, and determined to develop the products I was designing technologically, as well as visually, I began to moonlight as a professional.

My own success has been in observing objects in daily use which, it was always assumed, could not be improved.

The best kind of business is one where you can sell a product at a high price with a good margin, and in enormous volume. For that you have to develop a product that works better and looks better than existing ones.

—Book: The Dymaxion World of Buckminster Fuller

I was convinced that it was the role of a young designer to work in modern materials.

Mocked in the early stages of his career, Buckminster Fuller knew that the only way to make a genuine breakthrough was to pursue a vision with a single-minded determination in the face of criticism. If you try to change things then you upset the establishment, which is why invention and vilification have always gone hand in hand.

I was then to do what Buckminster Fuller did, to make real progress in the way we live, or think we live, it was not enough to be just a designer. You had to be an engineer as well. For the first time I saw how creative engineering could produce buildings and products that were not only technologically revolutionary, but whose visual effect, by its fidelity to, and generation out of, its engineering would be exciting, elegant, and lasting.

The term consulting engineer is a very vague one and in practice has been too much used to mean a man who for a consideration sells his name but nothing more. Now I never connect myself with an engineering work except as the Directing Engineer, who, under the Directors, has the sole responsibility and control of the engineering, and is therefore The Engineer

…In a railway the only works to be constructed are engineering works, and there can really be only one engineer.

It is in our engineers that we should place our greatest faith for the present, in that they determine the way our future will be. While novelists, painters and poets are making craven images to the present, ossifying it, offering to the future only ways of remembering, the engineers and inventors are determining how the future will work.

In art you place yourself at the mercy of human judgment and its odious courtiers, human error and human weakness. In engineering and design you are at the mercy only of natural law (physics) and the market (both development capital and income generated by response to the product).

The public has been easily convinced by advertising, and receptiveness to revolution has dwindled. Furthermore, such ‘invention’ as is now allowed is the prerogative of the multinationals, not people. Where are our Wright Brothers? Where have the Edisons gone? And the Henry Fords? They are not there. We have broken new frontiers, but where are the names? Who invented the space shuttle? The nuclear submarine? The wind farm? When you go for backing your crazy scheme it is not enough to be a man, you have to be a group of men. And where is the fun in that?

The only way to make real money is to offer the public something entirely new, that has style value as well as substance, and which they cannot get anywhere else.

I didn’t want to put the icing on other people’s creations. I wanted to make things.

Brunel would wake up and say to himself, ‘I want to design the first ocean-going vessel with a screw propeller, it’ll look great, be hugely efficient, and change the world.’ He didn’t wake up and think, ‘I think I’ll try mixing a few more oats in with the horse’s feed and see if it makes the cart go faster.’

Jeremy Fry had no regard for experts from other fields (always teaching himself whatever he needed to know as he went along) and he was an engineer interested in building things that derived not only excellence from their design, but elegance as well.

The next term I peaked in again, and they were all doing exactly the same thing with washing machine fascias. It was like some terrible Kafkaesque design nightmare—but showed me a bleak vision, early on in my career, of what it would be like to design things for other people. It seemed to me that to clock on at work in the morning and be told, ‘We’ve got this kettle, we want you to redesign it for us,’ was the very antithesis of Buckminster Fuller and Brunel.

It mattered not a jot that I had changed courses continually, from painting to furniture, to interior design, to engineering. I, like everyone else, was just looking for the most exciting thing to do with each moment.

One was a disastrous design theory that took inexplicable hold on the imaginations of so many, namely that simplicity was the key to perfect design. This was the period of Scandinavian design, of the renewed interest in the Bauhaus, and of men like Dieter Rams at Braun who decreed that all must be matt black and boxy. Designers were just picking up on a style, and then slavishly reproducing it. It was tantamount to designocide.

Plastic is no use at all in large flat surfaces – only make it curve, and it becomes phenomenally strong. Therein lies its unique potential, and therein always lay its beauty, the perfect beauty that comes with fidelity to function.

This attitude to employment extended to Fry’s thinking in everything including engineering. Like Brunel, he did not, when an idea came to hum, sit down and process it though pages of calculations; he didn’t argue it though with anyone; he just went out and built it.

So it was that when I came to hum, in the midst of my efforts with the Sea Truck that summer, to say, ‘I’ve had an idea,’ he would offer more advice than to say, ‘You know where the workshop is, go and do it.’ ‘But we’ll need to weld this thing,’ I would protest. ‘Well then, get a welder and weld it.’ When I asked if we shouldn’t talk to someone about, say, hydrodynamics, he would say, ‘The lake is down there, the Land Rover is over there, take a plank of wood down to the lake, tow it behind a boat and look at what happens.’

The root principle was to do things your way. It didn’t matter how other people did it. It didn’t matter if it could be done better. The Ballbarrow was not the only way to make a wheelbarrow that didn’t get stuck in a mud – but it was a way. The trick is not to keep looking over your shoulder at others, or to worry, even as you begin a project, that it is not going to be the best possible example of its kind. As long as it works, and it is exciting, people will follow you.

In business you will be wrong, by and large, 50 percent of the time. The trick is to recognize when you have gone wrong and correct the damage – not to worry, at the moment of making the decision, whether it is the right one.

I may have given the impression up to this point, with all my tales of individuality, frustration with the status quo and all that, that I was a self-indulgent, renegade student. Nothing could be further from the truth. I have been very boring, indeed, by no means your typical sixties wild child. I didn’t smoke or do drugs, I drank only very little, was pretty well organize, and disciplined, and I worked late at night in the holidays on all the projects that I was involved in. I wore the odd flowery shirt, and had quite long hair, but only because I thought they looked nice.

I regret that now, in a way. I saw my own son having a whale of a time at college, going out clubbing, drinking, never seeing daylight and doing all his work at the last minute. It is perhaps the only thing I actually regret not having conformed with. It is ironic, too, that there was so much more opportunity for me to have fun in the sixties than there was for him in the nineties, a youth culture so much more exciting that was there to be a part of.

Maybe it was just a desire to be rich and successful that motivate me – for I was motivated in almost a devilish way compared to the other students – but I think it had more to do with that running business, the wanting to get to the front and get away, and not have to look over my shoulder.

I learnt then one of the most crucial business lessons of my life: to stint on investment in the early stages, to try to sell a half-baked product, is to doom from the start any project you embark on.

People do not want all-purpose; they want high-tech specificity.

As with selling anything, it was about seeing how the boat would fit into the life of the customer, not about mouthing off about how great it was.

The entrenched professional is always going to resist far longer than the private consumer.

One decent editorial counts for a thousand advertisements. People are far more likely to believe someone who has tested something for themselves – and it is throughout my struggles to launch the Dual Cyclone, I made editorial comment the basis of all my thinking about publicity.

One of the strains of this book is about control. If you have the intimate knowledge of a product that comes with dreaming it up and then designing it, I have been trying to say, then you will be the better able to sell it and then, reciprocally, to go back to it and improve it. From there you are in the best possible position to convince others of its greatness and to inspire others to give their very best efforts to developing it, and to remain true to it, and to see it through all the way to its optimum point. To total fruition, if you like.

Debt is a terrible thing for a small company. It fosters a bizarre reverse psychology that comes from the darkest depths of the human psyche and makes you even more incline to overspend. The reason for this, is that when you have no money and are in debt you start thinking about all the things you could do if you had money, and that sets you to dreaming up all sorts of schemes and projects, which lead you into further debt as you try to realize them.

When you have the money, on the other hand, you tend to be more careful, largely because the occasion does not arise where you sit around desperately trying to think of ways of making money. You just get on with your life without thinking up hair-brained schemes you couldn’t possible carry out. Thus, without an overdraft you are not only freed of the interest burden, but your mind is freed to think more clearly and you can negotiate more effectively with both suppliers and customers, because they can see that you are not stretched financially and desperate to make a deal.

Slow, Slow, Slow. These things cannot be hurried. When you develop a prototype you have to change only one thing at a time. If you really going to improve things, and that is what inventing is all about, then you are going to have to be patient. Very patient.

It is often very difficult to justify a new product in the very early stages of its development and this leads to a cripplingly vicious circle, for the cost of development is huge, and it is just at this very time that one most needs an injection of outside cash.

Before I went into production with the Dual Cyclone, I had built 5,127 prototypes.

And all the while I was making cyclones. Acrylic cyclones, rolled brass cyclones, machine aluminum cyclones. For three years I did this alone. I could not afford anyone to help me, and what would have been the point, when I could do it all myself?

That is what development is all about. Empirical testing demands that you only ever make one change at a time. It is Edisonian principle, and it is bloody slow. It is a thing that takes me ages to explain to my graduate employees at Dyson Appliances, but it is so important. They tend to leap in to tests, making dozens or radical changes and then stepping back to test their new masterpiece. How do they know which change has improved it, and which hasn’t.

While it is easy, of course, for me to celebrate my doggedness now and say that it is all you need to succeed, the truth is that it demoralized my terribly. I would crawl into the house every night covered in dust after a long day in the coach house, exhausted and depressed because that day’s cyclone had not worked. There were times when I thought it would never work, that I would keep on making cyclone after cyclone, never going forwards, never going backwards, until I died.

If your principle skill, and first love, is design, invention and creation, as it was for both of us, then that is what you want to spend your time doing, rather than manufacturing, marketing, and selling.

It is inevitable if you are telling to sell a license for something – was offering everyone advance warning of a potential competitor.

Once the Japanese were convinced that the colours were right, and were happy with the design, they displayed a perfectionism that put my own to shame. They would tolerate not a single weld mark, not a scratch or a fleck of dust, not even a fingerprint. It was all part of their love for the product.

A licensee will very rarely give you a percentage of the ultimate retail price, which is what you want, because, he says, he can have no idea what the ultimate retail price will be. By taking a percentage of the manufacturer’s sale price, you relinquish all control over what the selling price to the consumer will be, and it that price that determines volume.

All their [Japanese] success is born out of a theory of gradual development that is very antithesis of the British obsession with the quantum leap.

If the banks and the City want instant returns then you go out and sell your old products harder and better than before, and you end up, as we did, with the most feted advertising industry in the world, and bugger all else.

There is distorted investment now, in advertising. If I spend $1 million on advertising I get an instant return. But the same spend on R&D might take ten years to show a return, if it ever showed one at all. Naturally, everyone goes for advertising instead, and without encouragement, they will continue to do so forever.

My mistake, I have to say, had been not insisting on a trigger date for the minimum royalties when I originally negotiated the deal. And you do not sign a license agreement without a trigger date, otherwise it can run and run for ever without your ever getting paid anything.

I was tearing my hair out as these doors were slammed in my face for the most obtuse reasons. The poor buggers were so wrong, to think that designers knew nothing about business, or about marketing, or about selling. It is the people who make the things that understand them, and understand what the public wants. It is men like these bankers who, by stripping the builders and makers of power, have run Britain into the ground.

Any little design improvement that you try to make will inevitably be used to exploit you by your opposition.

The thing about inventing is that it is a continual and continuous process, and it is fluid. Inventions generate further inventions. In fact, that is where inventions come from. They very rarely come out of nothing.

We made hundreds of little technical improvements to the cyclone, and to the cleaner head, and at the same time concentrated on reducing the number of screws, joins, and parts in the finished design—this would concentrate our minds on the essence of the function, and force the from to follow it most efficiently, and also, most importantly since we never knew how much money we were going to have put the thing in production, it could keep down the amount of tooling we needed.

Once you have ensured the stamina and strength of your space technology, the next thing is to do away with any gimmicks and gewgaws that might snap off or burn up during re-entry. There would, in short, be no silly knobs and buttons, such as air-fresheners and pile selecting dials. The design of vacuum cleaners, and most other domestic appliances has in recent years been beset by these pointless distractions purporting to offer futuristic advantages, which they patently do not. All those bits and bobs have more to do with lazy designers trying to make dull technology and poorly designed products look more interesting.

Everything was about function, and an over-designed look was the last thing I wanted – it is just that, as I will repeat to excess, the best looks come out of following the engineering.

Design Philosophy:

1. No one ever had an idea staring at a drawing board.

–Bacon always got his ideas from walking in the countryside and observing nature, rather than sitting in his study. So get out and look at things, and when an idea comes, grab it, write it down, and play with it until it works. Don’t sit and expect ideas to come.

2. Everyday products sell.

–Although it is harder to improve a mature product, if you succeed there is no need to create a market. Thinking in a vacuum is not going to help. Try out current products in your own home, and make a list of things that you don’t like about them – I found 20 things wrong with my Hoover Junior at the first attempt.

3. New Technology.

–The thing about truly new technology is that it makes your invention patentable. And then no one can copy it. You will find in the case of almost anything you dream up, someone, somewhere, may have done something vaguely similar before. This being the case, your job, in seeking a patent, is to point out how original and unique what you are doing is, compared to what they did.

–Initial patent around 20,000, but more if you don’t get patent on first submittal. Then about 2,000 ever year to renew per year.

4. The Edisonian Principle

–Engineering is a state of mind, or at least a method of working. You can become expert on anything in six months, but steer clear of projects that require too much maths, and stick to empirical things. You can achieve major breakthroughs by a bit of lateral thinking, and this approach will often lead to new inventions being born of each other.

–Keep testing and retesting and believe only the evidence of your own eyes, not to formulae or of other people’s opinions. No research can tell you what is going to happen.

5. Constant Revolution

–Constantly to rethink and improve every aspect and function, never being satisfied until you have solved every problem. And further patents are crucial. The only way to keep possession of your invention is to keep strengthening it.

6. Expressive design

–To start thinking from the outside is to doom the project from the outset. If your first though, as a computer designer, for example, is that keyboards ought to be cruciform, dimpled, and purple, with fluffy bits on the corners and a slight smell of rose-hip, then you have probably not come up with anything useful or patentable.

–But once you have established your technology, then you can produce a design that accentuates it.

–Good design, generated out of the function of the thing, will explain why it is better, and why it should be bought.

–Alec Issigonis, who invented the Mini, believed that design was about integrating new technology to improve function, not simply about styling.

–Products can only begin to be beautiful when they work well. And then you can allow the form to follow function. Then be different for its own sake.

–Conventional looks do not make a product more marketable. How is the poor customer to know it is different from the rest, if it looks the same?

7. Stamina and conviction.

–It will take longer than you imagined. Ten years of development? Do you fancy that? And then negotiations on a knife edge, a shoestring budget, and hanging by a thread? It will take balls.

8. Total control

–From the first sprouting of the idea, through research and development, testing and prototyping, model making and engineering, drawings, tooling, production, sales and marketing, all the way into the homes of the nation, it is most likely to succeed if the original visionary (or mule) sees it right through.

I was 31 years old when I tore the bag off my Hoover and stuck a cereal packet in the hole. 2 May 1992 was my 45th birthday (the first fully operational Dyson Dual Cyclone).

Toolmakers are like builders in many ways. Whatever they quote you fro the work, they are sure to start increasing that price every time you make even the smallest change to your order – it is practically built in to their financial planning. Even if the changes you make result in the tool you require being smaller and simpler, you will find that they double their price. And you have to expect that.

It is received wisdom in the appliance market that brand is important. Brand is only important when two products are identical; it is not important if one of the products has better technology or a better design than the other.

That brand dependence was quite simply shattered when the Dyson came along, because it gave the consumer, for the first time since men wore top hats in town and rode horses to work, the choice of something better. And suddenly the customers had something other than brand name to look at. We even went so far as to make our own brand name not very clear, which emphasized the point. If you are selling cornflakes or cola than branding is all important – it out to mean nothing when you are selling technology.

Not only do manufactures plant their own stooges, I discovered, but they sell their cleaners to sales staff, at discounts, to convert them to their product. When I tried this it was described as ‘a clever trick’, as if to insinuate that it was underhand, by people who had been at it for years. The only clever thing about it was the retail staff liked my product more than any of the others, bought it in large numbers, and then sold it with greater conviction.

Anything advertising can do, true journalism can do better.

…Who is it that gets neglected? The inventor, that’s who. The designer, the engineer, the chemist, the brewer, the boffin. The people obsessed by the product; who willingly accept that the sizzle is important, but who get their kicks trying to make an ever better steak.

Car companies used to be run by people who loved cars. They knew how to make cars themselves, and were always trying to make them better. Retail companies used to be run by people who loved shops, and a hundred something years ago, George Safford Parker was nutty about fountain pens.

As business got bigger and more complex, these obsessive, impractical, product-driven enthusiasts couldn’t cope. They had to be helped by money men and lawyers and marketing persons with advertisement agents.

From that moment, the status of the maker in this country has been in decline. And the rise and rise of marketing persons, through no fault of their own, has done nothing to help…it might even be, I think, that the erosion of our manufacturing sector, and the rise and rise of our service sector, is in part connected with the de-coupling of making things from marketing things. [Jeremy Bullmore, Marketing Magazine December 1995]

Everyone who starts work at Dyson makes a vacuum cleaner on their first day.

Engineering and design are not viewed as separate. Designers are as involved in testing as engineers are in conceptual ideas.

–Elsewhere in industry, designers just design the look of the product, and maybe sketch the odd part. Then engineers design the mechanics of the product. Test engineers do the testing. And model makers make the models. And machinists machine things. At Dyson, uniquely, we see no barriers between these disciplines – everyone in the department does everything. This way, everybody understands the implications of what they are doing, and enjoys total creative freedom.

I’d rather the qualities of my employees shone through in what they did, rather than what they wore. That is why I employ brilliant young graduates with no experience at all. I want free-thinkers who can take the company forward, and have revolutionary ideas.

You are just as likely to solve a problem by being unconventional and determined as by being brilliant. And if you can’t be unconventional, be obtuse. Be deliberately obtuse, because there are 5 billion people out there thinking in train tracks, and thinking what they have been taught to think.

If you go in and be illogical, then half the time people will laugh at you, and half the time you will strike up something interesting because you have stopped everyone else from thinking logically, which has failed to provide a solution. Be a bit whacko and you shake people up a bit. And we all need shaking up.

Employ graduates straight from university. The basic reason for this is that they are unsullied. They have not been strapped into a suit and taught to think by a company with nothing on its mind but short-term profit and early retirement. We are trying to do things differently from everyone else, so it’s easier to teach fresh graduates this new way, and enable them to challenge established beliefs, than to retrain someone with ‘experience.’

Everything in the factory is, in fact, done by hand, because we do not keep the tooling here, or manufacture any of the components, thus keeping nasty, heavy, dirty machinery out of the place, and making it feel more like a craft workshop – albeit a very modern one – than a factory.

We are fascinated, to the point of obsession, with the product. We do not, perhaps, attain quite the delirious object fetishism of the Japanese, but are determined that whatever we produce should be perfect, as well as exciting and beautiful. It is this that allows us to maintain ownership of our product, and without it we do not have a business.

There are four straightforward requirements that we have of our suppliers; that they should provide (a) what we order, (b) at the time stipulated, (c) in the correct quantity, (d) to the quality stipulated.